Auto Air Conditioning Service

The Switch to R-1234yf

R-134a was originally the replacement for R-12 which was phased out because of the harmful affects it had on the ozone layer. Fast forward and we now know that R-134a is contributing to global warming and so begins the phasing out of it to be replaced with the new guy in town, R-1234yf. R-134a and R-1234yf have many similar properties. This is because R-134a is a hydrofluorocarbon (HFC) while R-1234yf is a hydrofluoro-olefin (HFO) refrigerant. They are both made up of hydrogen, flourine and carbon atoms. But, the big difference between the two refrigerants is that R-134a has a GWP (Global Warming Potential) of 1300 while R-1234yf has a GWP of less than 1!

The refrigeration cycles of the two refrigerants are very similar as the pressure and temperature relationship of the two are similar. The servicing procedures however, are quite different. Recovery and recycling of the refrigerant is a bit more complicated with the R-1234yf due to the sophistication of the equipment required. We have special A/C servicing machine dedicated to the R-1234yf refrigerant. Vehicles equipped with this refrigerant have different service fittings which prevents any potential cross-contamination of the two refrigerants. This equipment must be approved by, and registered with the EPA. It must follow the SAE standard J2843, “R-1234yf (HFO-1234yf) Recovery/Recycling/Recharging Equipment for Flammable Refrigerants for Mobile Air-Conditioning Systems,” which establishes minimum equipment requirements for the recovery/recycle/recharge of R-1234yf refrigerant. In addition, technicians need to be Section 609 certificated to buy and work with R-1234yf. Currently, the price of the new R1234yf is 10 times more costly than the R134a refrigerant. The cost should begin to come down as of model year 2021, all US vehicles will no longer be permitted to use the R-134a refrigerant. Fear not, at Auto Care Plus our technicians are fully trained and certified to service your R-1234yf equipped vehicle! If your AC isn’t blowing cold trust the pros at Auto Care Plus to keep you cool on those hot summer days!

R12 to R134a

Should a major problem arise from your auto air conditioner, you may encounter new terminology. Words like “retrofit” and “alternative refrigerant” are now in your mechanic’s glossary. You may be given an option of “retrofitting”, as opposed to merely repairing and recharging with Freon. Retrofitting involves making the necessary changes to your system, which will allow it to use the new industry accepted, “environmentally friendly” refrigerant, R-134a. This new refrigerant has a higher operating pressure, therefore, your system, dependent on age, may require larger or more robust parts to counter its inherent high-pressure characteristics. This, in some cases, will add significantly to the final cost of the auto air conditioner service And if not performed properly, may reduce cooling efficiency which equates to higher operating costs and reduced comfort.

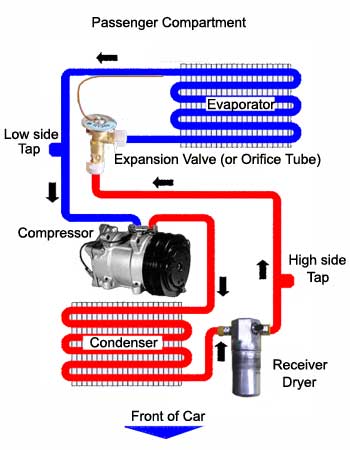

Vehicles are found to have primarily three different types of air conditioning systems. While each of the three types differ, the concept and design are very similar to one another.

Vehicles are found to have primarily three different types of air conditioning systems. While each of the three types differ, the concept and design are very similar to one another.

A/C Components

The most common components which make up these auto air conditioner systems are the following:

- COMPRESSOR

- CONDENSER

- EVAPORATOR

- ORIFICE TUBE

- THERMAL EXPANSION VALVE

- RECEIVER-DRIER

- ACCUMULATOR.

Note: if your car has an Orifice tube, it will not have a Thermal Expansion Valve as these two devices serve the same purpose. Also, you will either have a Receiver-Dryer or an Accumulator, but not both.

Note: if your car has an Orifice tube, it will not have a Thermal Expansion Valve as these two devices serve the same purpose. Also, you will either have a Receiver-Dryer or an Accumulator, but not both.

Compressor

Commonly referred to as the heart of the system, the compressor is a belt driven pump that is fastened to the engine. It is responsible for compressing and transferring refrigerant gas.

The auto air conditioner system is split into two sides, a high-pressure side and a low-pressure side; defined as discharge and suction. Since the compressor is basically a pump, it must have an intake side and a discharge side. The intake, or suction side, draws in refrigerant gas from the outlet of the evaporator. In some cases, it does this via the accumulator.

Once the refrigerant is drawn into the suction side, it is compressed and sent to the condenser, where it can then transfer the heat that is absorbed from the inside of the vehicle.

Condenser

This is the area in which heat dissipation occurs. The condenser, in many cases, will have much the same appearance as the radiator in you car as the two have very similar functions. The condenser is designed to radiate heat. Its location is usually in front of the radiator, but in some cases, due to aerodynamic improvements to the body of a vehicle, its location may differ. Condensers must have good air flow anytime the system is in operation. On rear wheel drive vehicles, this is usually accomplished by taking advantage of your existing engine’s cooling fan. On front wheel drive vehicles, condenser air flow is supplemented with one or more electric cooling fan(s).

As hot compressed gasses are introduced into the top of the condenser, they are cooled off. As the gas cools, it condenses and exits the bottom of the condenser as a high-pressure liquid.

Evaporator

Located inside the vehicle, the evaporator serves as the heat absorption component. The evaporator provides several functions. Its primary duty is to remove heat from the inside of your vehicle. A secondary benefit is dehumidification. As warmer air travels through the aluminum fins of the cooler evaporator coil, the moisture contained in the air condenses on its surface. Dust and pollen passing through stick to its wet surfaces and drain off to the outside. On humid days you may have seen this as water dripping from the bottom of your vehicle. Rest assured this is perfectly normal.

The ideal temperature of the evaporator is 32° Fahrenheit or 0° Celsius. Refrigerant enters the bottom of the evaporator as a low-pressure liquid. The warm air passing through the evaporator fins causes the refrigerant to boil (refrigerants have very low boiling points). As the refrigerant begins to boil, it can absorb large amounts of heat. This heat is then carried off with the refrigerant to the outside of the vehicle. Several other components work in conjunction with the evaporator. As mentioned above, the ideal temperature for an evaporator coil is 32° F. Temperature and pressure regulating devices must be used to control its temperature. While there are many variations of devices used, their main functions are the same; keeping pressure in the evaporator low and keeping the evaporator from freezing; A frozen evaporator coil will not absorb as much heat.

Pressure-Regulating Devices

Controlling the evaporator temperature can be accomplished by controlling refrigerant pressure and flow into the evaporator. Many variations of pressure regulators have been introduced since the 1940’s. Listed below, are the most commonly found.

Accumulators

Accumulators are used on systems that accommodate an orifice tube to meter refrigerants into the evaporator. It is connected directly to the evaporator outlet and stores excess liquid refrigerant. The introduction of liquid refrigerant into a compressor can do serious damage. Compressors are designed to compress gas not liquid. The chief role of the accumulator is to isolate the compressor from any damaging liquid refrigerant. Accumulators, like receiver-driers, also remove debris and moisture from a system. It is a good idea to replace the accumulator each time the system is opened up for major repair and anytime moisture and/or debris is of concern. Moisture is enemy number one for your A/C system. Moisture in a system mixes with refrigerant and forms a corrosive acid. When in doubt, it may be to your advantage to change the Accumulator or receiver in your system. While this may be a temporary discomfort for your wallet, it is of long term benefit to your air conditioning system. The accumulator is required to be replaced anytime the system is opened up for service or replacing of components. Failure to do so will void any warranty on those parts. Another reason why you should trust your vehicle to the professionals who are trained and certified to work on your air conditioning system. Like the ones here at Auto Care Plus!